ulf 2

Clean aerodynamics and an unusual, but fuel efficient power plant contribute to an ultralight motor glider with significantly reduced direct operating cost. The wingspan of eleven meters provides good soaring capabilities. A four-stroke, two-cylinder car engine guarantees far lower fuel consumption than comparable ultralight aircraft. An other attractive feature is the aircraft’s low onboard and external noise levels. Muffler, catalytic converter and the use of lead free gasoline reduce ecological damage to a minimum. A fuselage integrated aircraft rescue system offers additional safety in emergency situations.

The single seat ULF-2 ultralight motor glider was designed by Dieter Reich. Anton Quanz built the prototype aircraft. Horst Fischer was responsible for engine installation and electric system.

First flight was in October 1993. In February 1995 the ULF-2 design received an airworthiness certificate issued by the DAeC (German Aeroclub). In June 1997, Dieter Reich was awarded the OUV “Hans-Becker-Prize” for design and development of ULF-2. The first homebuilt aircraft flew in 1999. more than 20 ULFs are in operation in Germany.

So far, over 100 licenses have been issued, and a total of around 40 Ulf-2s are in operation.

EEL ULF-2 Microlight

Handling Qualities

A moderate wing taper ratio in conjunction with a “harmless” airfoil results like ULF-1 in an aircraft which can be considered spin resistant.

By pulling the stick, the aircraft can slowly be stalled in straight level flight. At 75% max. engine power and a deceleration of 2 km/h per second the aircraft reaches a steady state equilibrium at a rather high

angle of attack and a speed of about 48 km/h. In this state there is no loss of altitude. The aircraft can be controlled by using rudder and aileron as in normal flight.

At engine idle, equilibrium speed is about 50 km/h. The stick is in max. pull position. The aircraft performs a slight longitudinal oscillation. There is no tendency for wing drop. The sink rate is 2 – 3 m/s. The aircraft can be controlled by using rudder and aileron as in normal flight.

When the airplane will dynamically be stalled, there is a moderate nose-down movement but no tendency to enter a spin. The aircraft accelerates and recovers. The loss of altitude is less than 40 m.

The economical cruise speed is 120km/h with a fuel comsumption of 5,8l/h.

Construction

ULF-2 is specially suited for selfbuilders. Major construction materials are northern pine or Douglas fir, spruce and birch plywood. Fibreglass/epoxy is used for engine cowling, wing tips and fairings. The airframe is covered with fabric. Steel tubes are used for engine mount, aluminium tubes for control rods. Wing spar fittings, elevator hinges, stabilizer attachment, elevator and rudder horn are made of steel. Landing gear suspension, control system bell cranks etc. are manufactured of aluminium sheet/plate material.

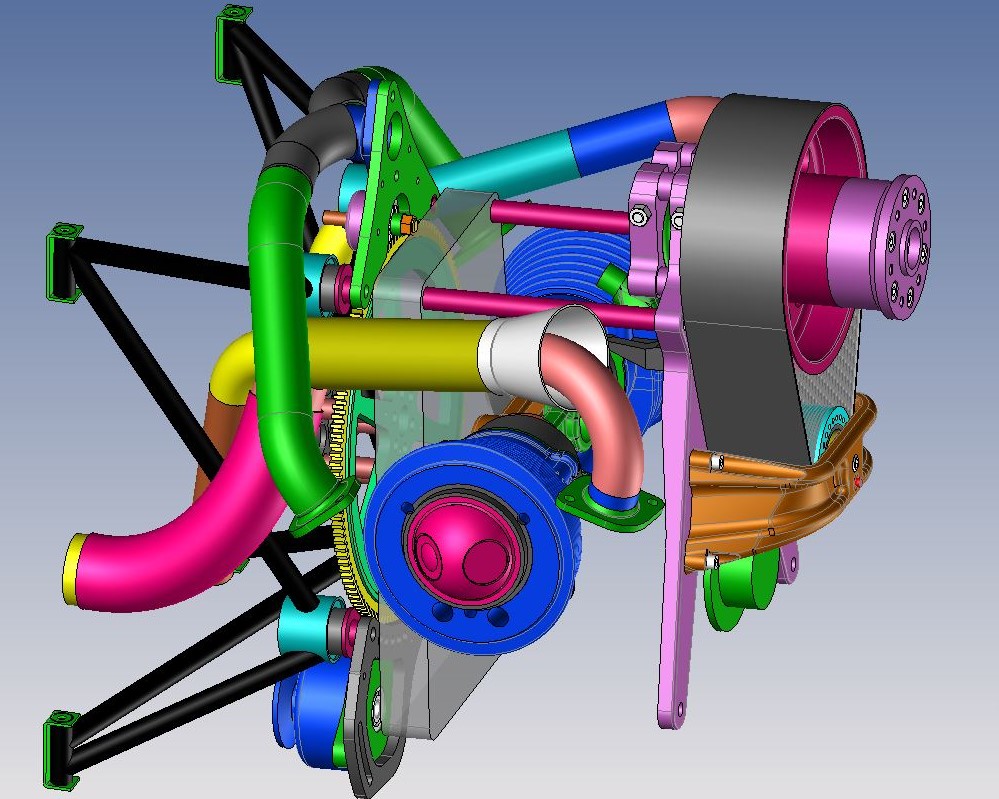

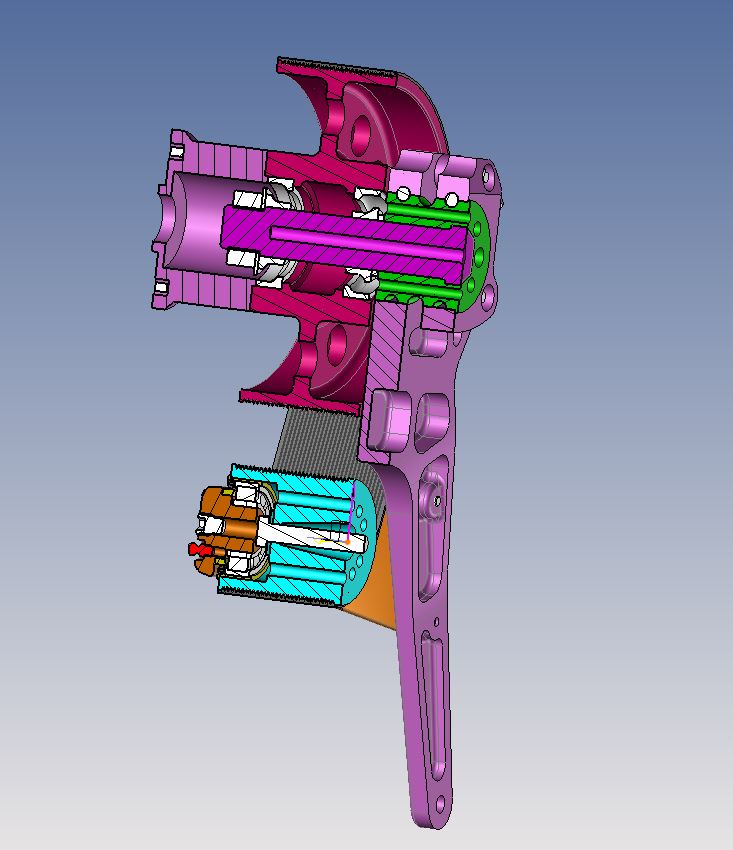

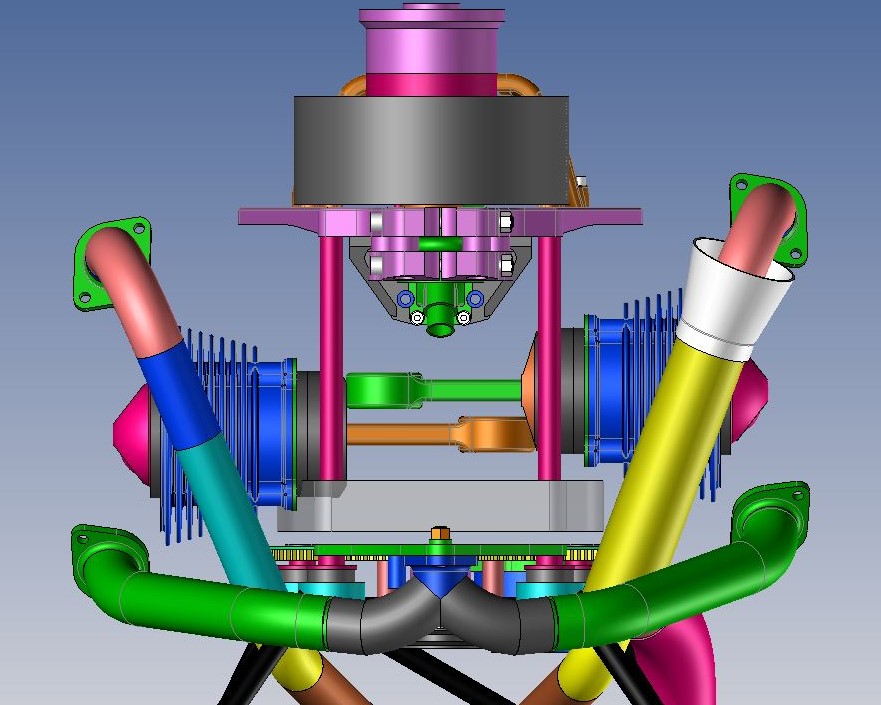

Propulsion

The propulsion system consists of the 24 kW, 4 stroke, 2 Cylinder (opposed) CITROËN-VISA car engine, a belt driven reduction gear and a muffler to reduce exhaust gas noise. The engine is driven by lead free gasoline. The decontamination of the exhaust gases is accomplished by a catalytic converter. Carburettor air is filtered and sent through a manually controlled carburettor air heater.

Rescue System

The fully integrated ballistic rescue system consists of a parachute, which is packed into a container, located behind the pilot’s seat. An electrically or mechanically ignited rocket pulls out the chute and rescues aircraft and pilot.

Road Transport

Transport and storage should be done in an enclosed car trailer. By means of gimbal joints, the wings can be pulled away from the centre wing, and folded backwards alongside the fuselage. The detachable horizontal tail will be located between fuselage and wing. To unload the trailer and rigging the aircraft, one person needs about 25 minutes.

The folded airplane requires the following box dimensions: width:

1.65 m; length: 6.7 m; front height: 2.0 m; height at 2 meter: 2.0 m; height at 6.7 meter: 1.7 m.

Plan packs

A plan pack is available comprising of:

A complete set of 29 blue prints (15 sqm); most of them are full scale, including full-scale computer generated lines for wing and tails. Five plans are dedicated to the installation of the CITROËN-VISA car engine.

26 shop drawings (A4).

A 50 page construction manual with many photographs, an inspectors test and check list.

A 20 page flight-/operation manual.

All descriptions and manuals are in English language (metric units). Total time to build ULF-2 will be in the order of 2000 hrs. Cost of material including engine and rescue system is estimated to be about EURO 9000.

Certification

In Germany all ULF-2 aircraft constructed under license are considered airworthy and permitted to be flown, provided the following requirements are met.

1. Construction supervision by an authorised inspector, according to the check-/test instructions as written in the ULF-2 construction manual, followed by a detailed final inspection.

2. Annual condition inspection by an authorised inspector.